Recycling Rigid PU Foam Residues

Technology:

H&S technology of rigid PU foam recycling is based on the glycolysis method where PU residues are being dissolved in a mixture of glycol and catalysts. The highlight of H&S method is that in comparison to previously known glycolysis technologies recovered polyols do not contain hazardous primary aromatic amines which is being achieved through a deamination phase.

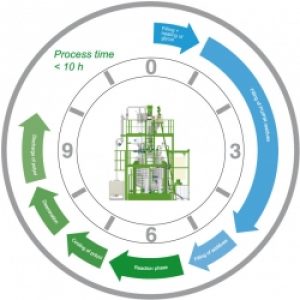

Process sequence and duration:

Raw materials required for the process:

PU/PIR residues:

Grind residues from rigid PU/PIR foam production (insulating panels, shells, blocks etc.) residues might contain paper, aluminum or fiber glass in the acceptable range. Often the residues should be purified/separated prior to the processing. H&S offers solutions for separation of the PU/PIR foam particles from facers. The remaining percentage of the impurities is being removed from the recycling polyol by means of the filtration.

Diethylene glycol:

is an organic compound. DEG is widely used in production of unsaturated polyester resins, plasticizers, acrylate and methacrylate resins and urethanes.

Catalyst, additves:

———————————————————————————————————————————————————————–

Example recipe:

PU foam industrial waste 44

DEG 50

Catalyst, additves 6

———————————————————————————————————————————————————————–

Properties of the recoverd polyol:

Hydroxyl number: 350 to 600 mg de KOH / g

Acid number: 3 to 15 mg de KOH / g

Amine number: 20 to 40 mg KOH / g

Viscosity (25 °C): 2.000 – 8.000 mPas

Appearance: viscous liquid of dark-brown color

———————————————————————————————————————————————————————–

Recovered polyol can substitute:

up to 30% of the basic polyol

————————————————————————————————————————————————————————-

without any influence on the physical and mechanical properties of the PU foam.

In spite of that OH number of recovered polyol is higher than the OH number of the original basic polyol it is not necessary to increase the isocyanate index in the formulation when adding recovered polyol. It can be explained by the fact that polyols based on H&S technology already contain parts of polyisocyanurate and polyurethane molecules originating from PU foam. In some cases it is even possible to reduce the isocyanate index.

————————————————————————————————————————————————————————————————————————————–

The manufacturing costs of the recycled polyol are approximately 30% lower than the market price for original polyol.

The physical and mechanical properties of the PU/PIR foam produced with recovered polyol are comparable with reference samples manufactured without recycled polyol.

Physical and mechanical properties of the rigid PU foam in comparison to original foam produced on a continuous lamination line (example)

Control sample (original PU foam) PU foam with recycled polyol

Percentage of the recycled polyol used (%) 0 20

Density (kg/m3) 29 29

Compression (%) 250 246

Counter rise strength (kg/m3) 90 89

Lambda coefficient 0,0230 0,0225

Isocyanate index 260 230

————————————————————————————————————————————————————————————————————————————–

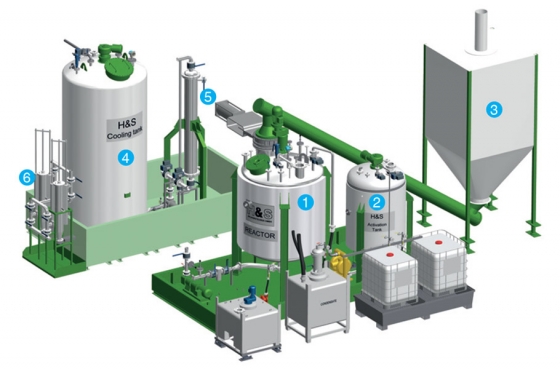

Reactor and peripheral equipment:

core unit

1. Réactor

2. Feeding system for PU residues tank

3. Cooling tank

4. Heat exchanger

5. Filtration system

Rigid foam reactors can be supplied with batch capacity from 1t to 5t or bigger if required.