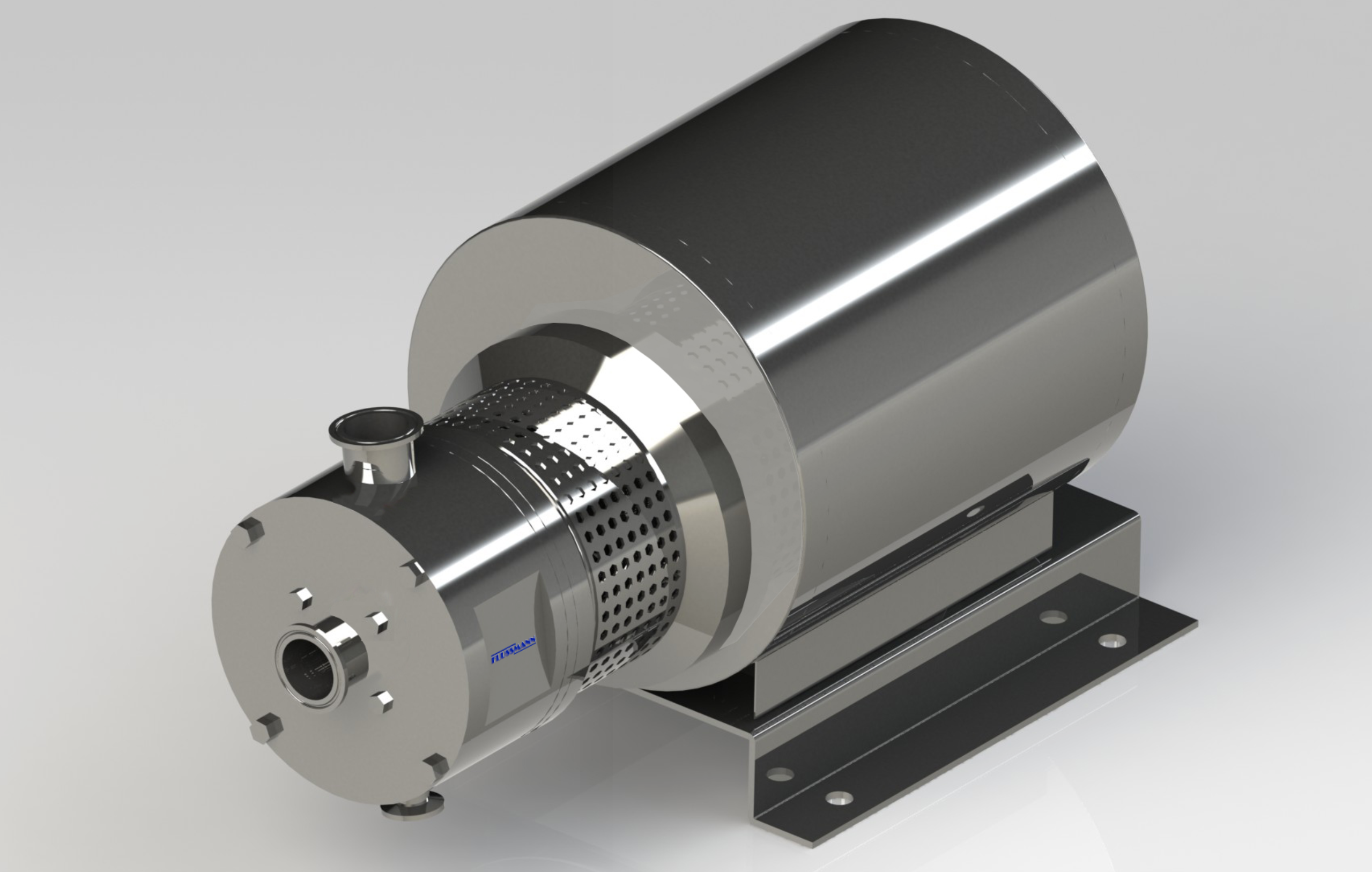

Dynamic Inline Mixer FIM

The FIM series of high-shear inline mixers offers the ability to pump, disperse, homogenize, and emulsify products with a single equipment. Many chemical, food, pharmaceutical, and cosmetic production processes require this system due to the limited space inside tanks for bottom mixers or vertical mixers.

.

.

.

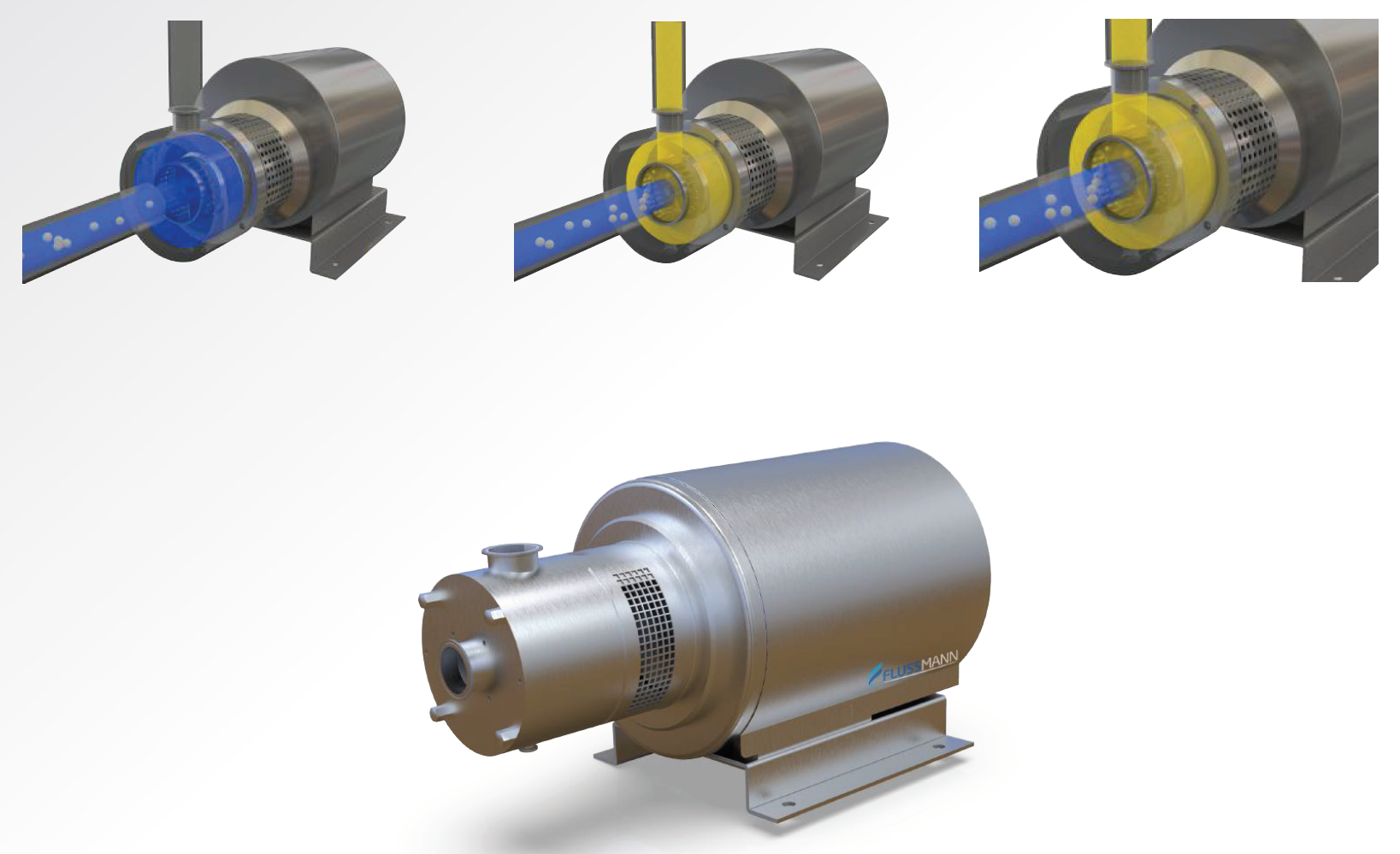

Operating Principle

The FIM mixer creates high shear through a high rotor speed and tight clearances between the rotor and stator.

The product is drawn in through the inlet and pushed by the rotor towards the stator.

Passing through the stator slots, the product is mechanically sheared, with particles being sheared by the rotor at a speed of over 20 m/s.

The flow is hydraulically sheared as it passes through the stator slots at high speed.

If the viscosity of the product is higher than 200 cP, it is recommended to add a pump at the mixer inlet.

.

Materials:

- Product-contact parts: AISI 316L

- Other stainless steel parts: AISI 304

- Mechanical seals: C/SiC/EPDM

- Gaskets: EPDM

- Surface finish: <0.8 µm

.

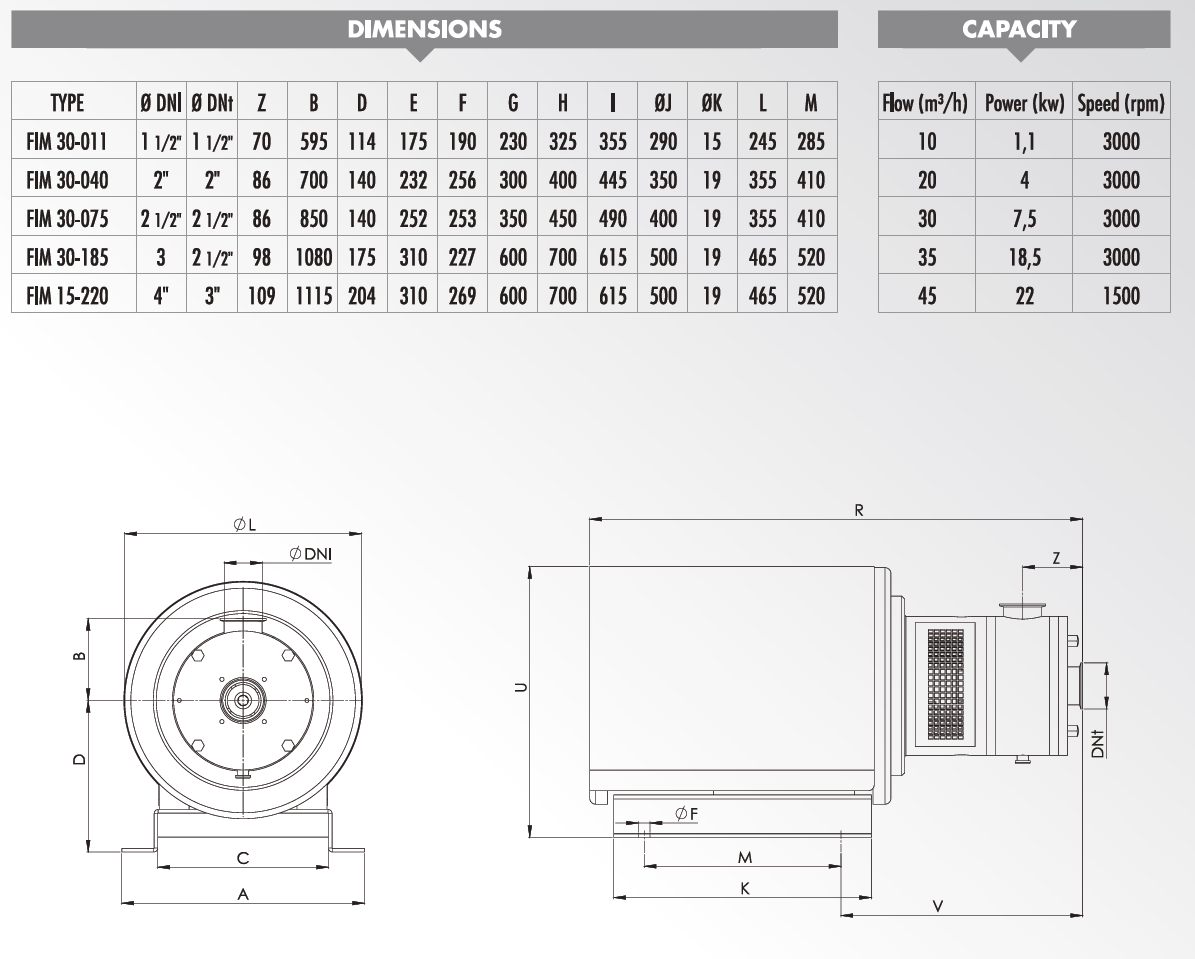

Design and Functionality:

- High shear, particle size reduction to less than 100 microns

- Simple and hygienic mechanical seal

- Various interchangeable working heads

- Easy to clean

- Standard connections: Clamp ISO-2852

- Motor mounted on support

Download our documentation in PDF format: