Description:

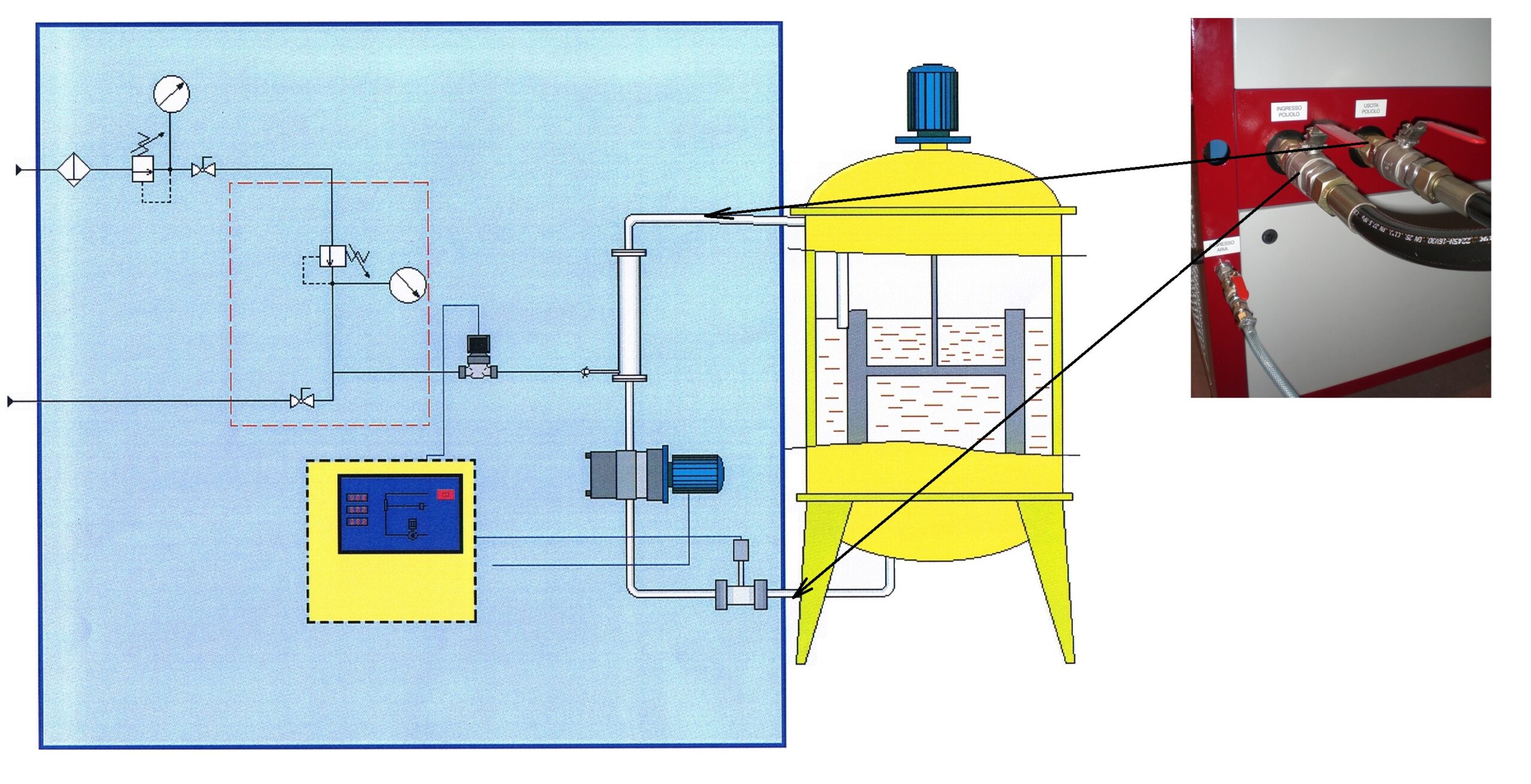

This machine consists of a steel frame containing all the necessary components for its operation, such as pipes, engine, pumps, valves, tanks, control panel, and instruments. It is a fully autonomous system, controlled through a touchscreen color display.

The touchscreen control system provides startup, production, and weekend modes, as well as constant display of measurement values, faults, and a help menu.

A set of static mixers allows for homogeneous dissolution of gas into the Polyol.

A densimeter continuously measures the Polyol and adjusts the required amount of air.

The Polyol is taken from the tank, transferred to the mixers through a gear pump, and returned to the tank.

The nucleation rate is constantly monitored and adjusted by an automation system.

The nucleator can easily be adapted to an existing installation.

The nucleation air is directly taken from the tank to avoid pressure variations.