FTS Twin Screw Pumps

Applications:

Twin screw pumps are ideally suited for low shear and gentle handling of products due to their operating mode and construction. The axial flow movement without change of direction, along with the non-contacting screws, provides optimal results.

.

Operating Principle:

The pair of screws rotates inside the pump casing, creating multiple separate chambers and pushing the trapped fluid inside based on the screw progression. The flow is particularly smooth and pulsation-free, with the pumped fluid flowing in an axial direction (rather than circumferentially, as is the case with centrifugal pumps). The result of screw rotation is a gentle movement of the displaced volume under non-turbulent conditions, making it ideal for handling shear-sensitive fluids or liquids easily prone to emulsion.

.

.

Design:

Max Flow Rate: 110m3/h

Max Particle Size: 23mm

Max Pressure: 20bar

Speed Range: 10-3500 rpm

Surface Finish: Ra< 0.6um ; EP=RA0.4um

Operating Temperature: -40°C to 150°C

.

Materials:

Product Contact Parts: AISI316 L

Other Parts: AISI304

Seals: EPDM/FKM

Mechanical Seals: SIC/C/EDPM, SIC/C/FKM, TC/TC/EPDM, TC/TC/FKM

..

.

Advantages:

Proportional capacity with speed

Compact construction

Direct drive without speed reduction possible

Suitable for nearly all media and fluids

High viscosities possible

Low pulsation

Low noise level

Dry-running possible

Constant flow under varying pressures and volumes

Simple pumping direction change

Easy replacement of pumping elements

Easy maintenance

Wide range of applications

Self-priming

.

.

.

.

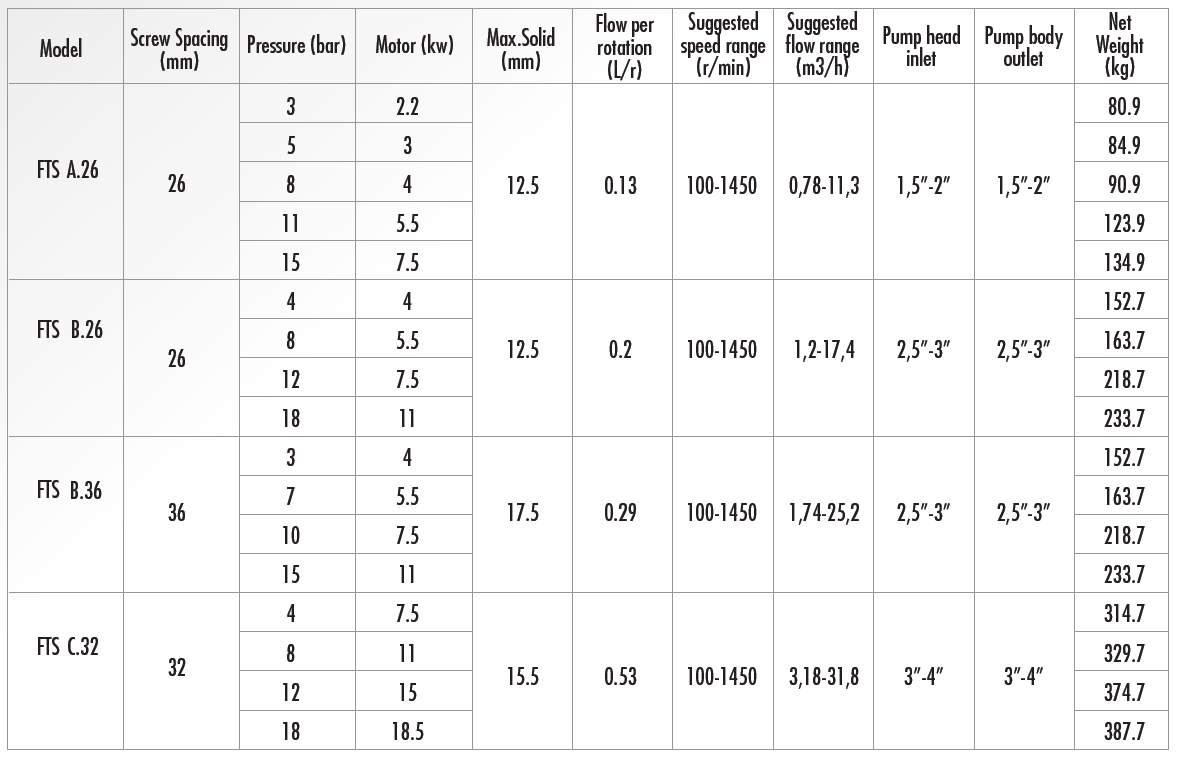

Motor Selection Table: