Lower Side Entry Agitator FSEA

Application:

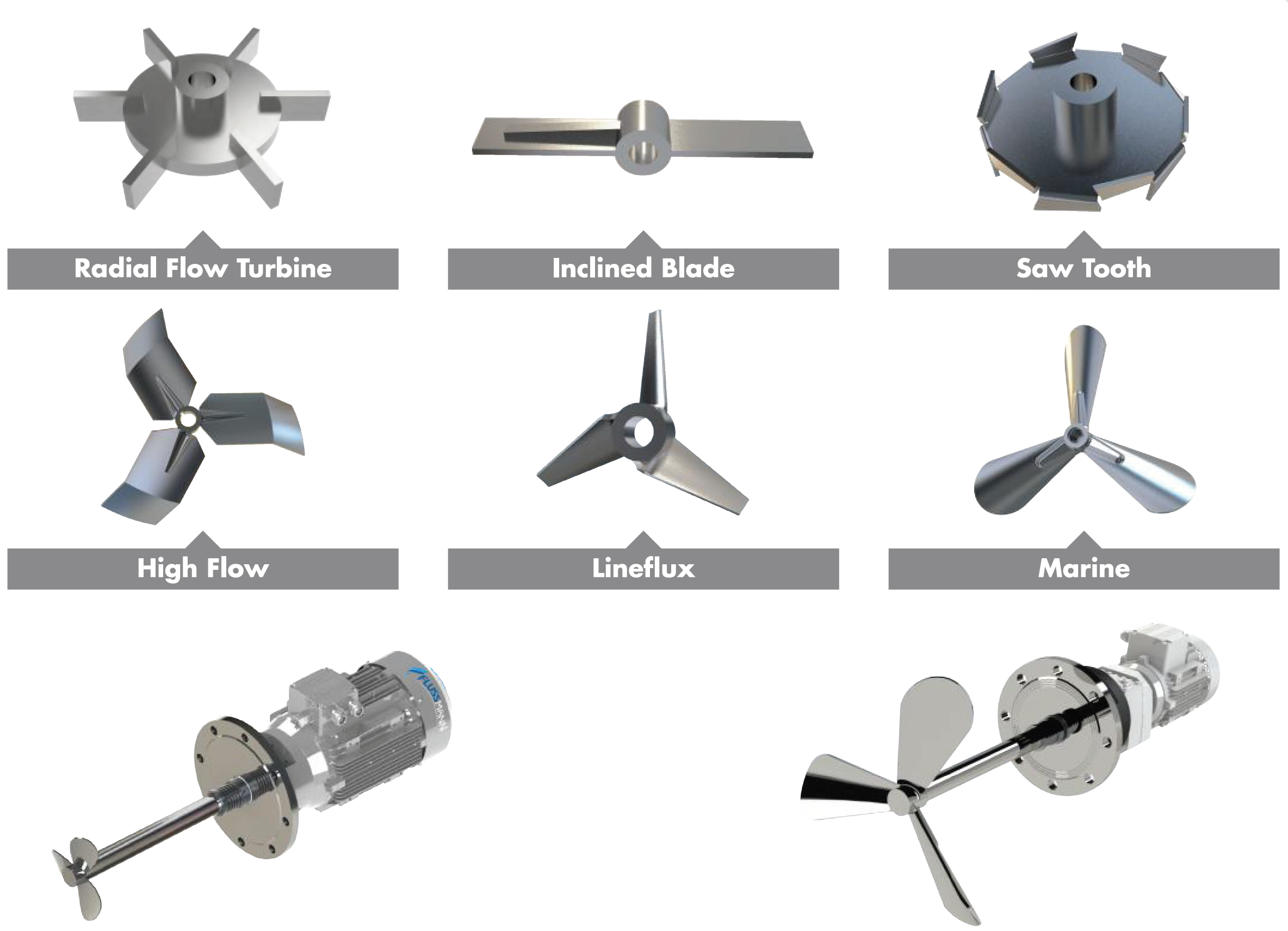

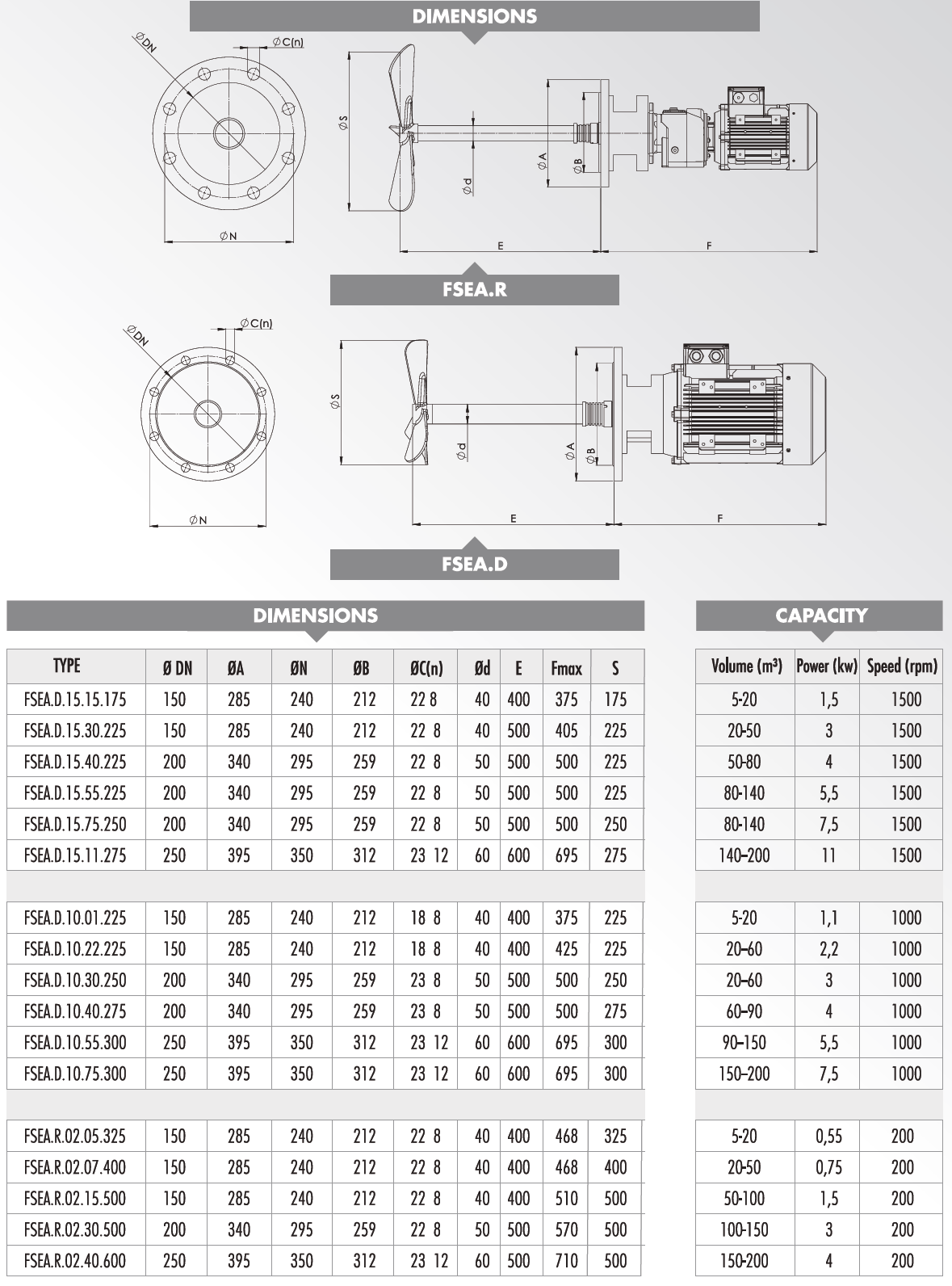

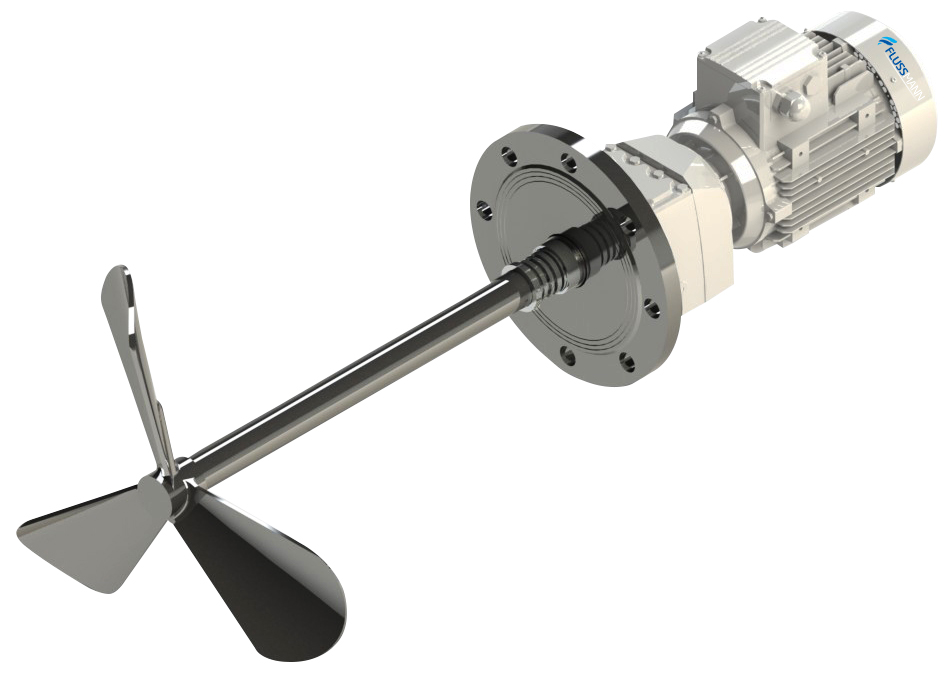

Side entry agitators with direct-coupled motor or motor-driven and cast bearing housing, impeller, and single mechanical seal. Suitable for mixing low-viscosity products in various chemical, food, and pharmaceutical applications such as wine, oil, milk, beer, and alcohol in large volume tanks.

.

Operating Principle:

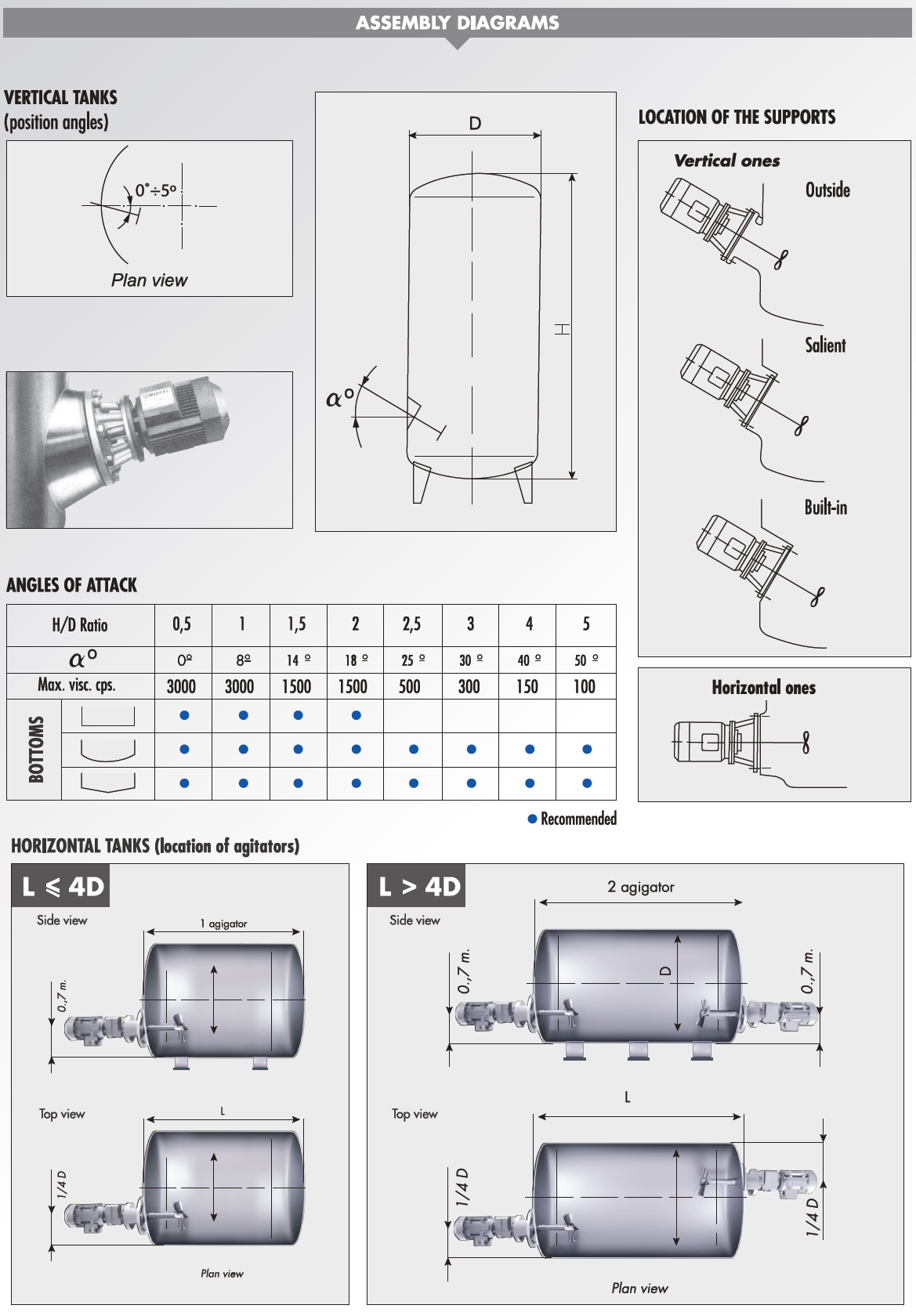

Side entry agitators are installed in an inclined position. The impeller creates a flow that pushes the product towards the bottom of the tank. The flow rises to the surface against the wall opposite the agitator. The effect is enhanced if the bottom is curved. The agitation is centrally distributed to increase the circular flow. This ensures complete homogenization of the product.

.