Benefits of the dispenser:

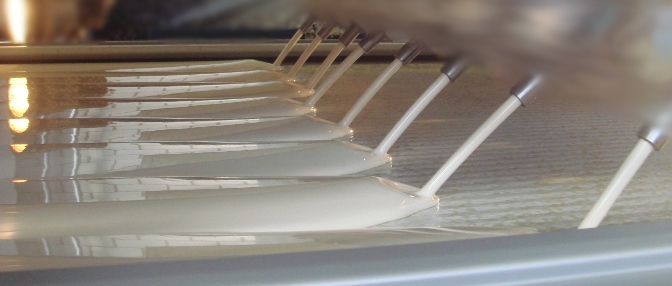

The quality of the polyurethane foam for sandwich panels produced continuously is strongly dependent on the control of the wave. If the speed of the line is not well controlled and if the contact point of the wave with the top of the facing is not well positioned the mechanical properties of the produced panel decrease considerably.

The spreading system mostly used mostly used at present is the “Poker”, a rake which oscillates in different speeds from left to right and from right to left of the panel. We settle generally a covering around 60 % on the return to the rake. This system contains numerous inconveniences: the distribution is very difficult to make homogeneous, make it cover the foam tends to crush cells in formation of the first passage and the wave is not uniform, thus difficult to adjust.

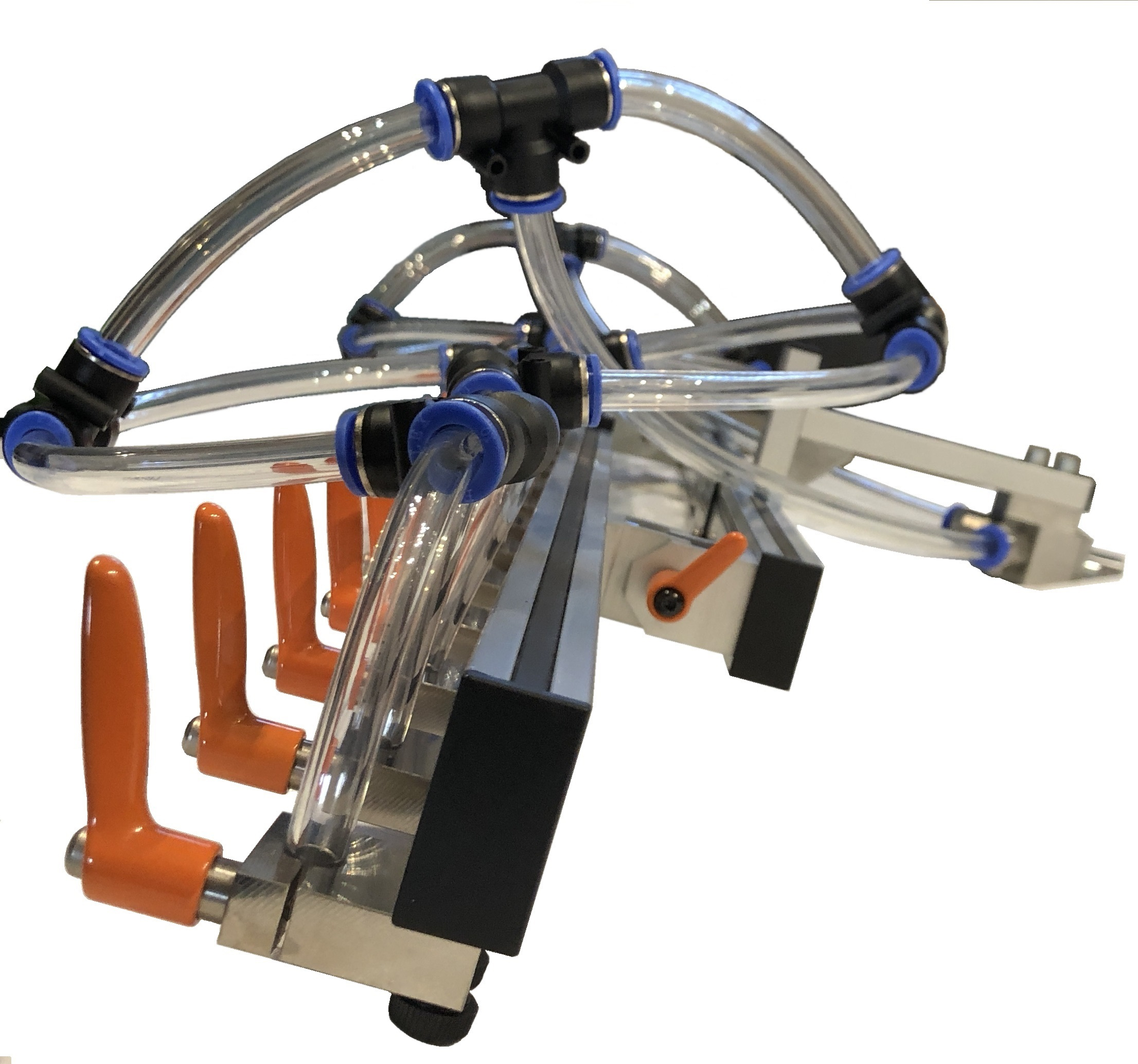

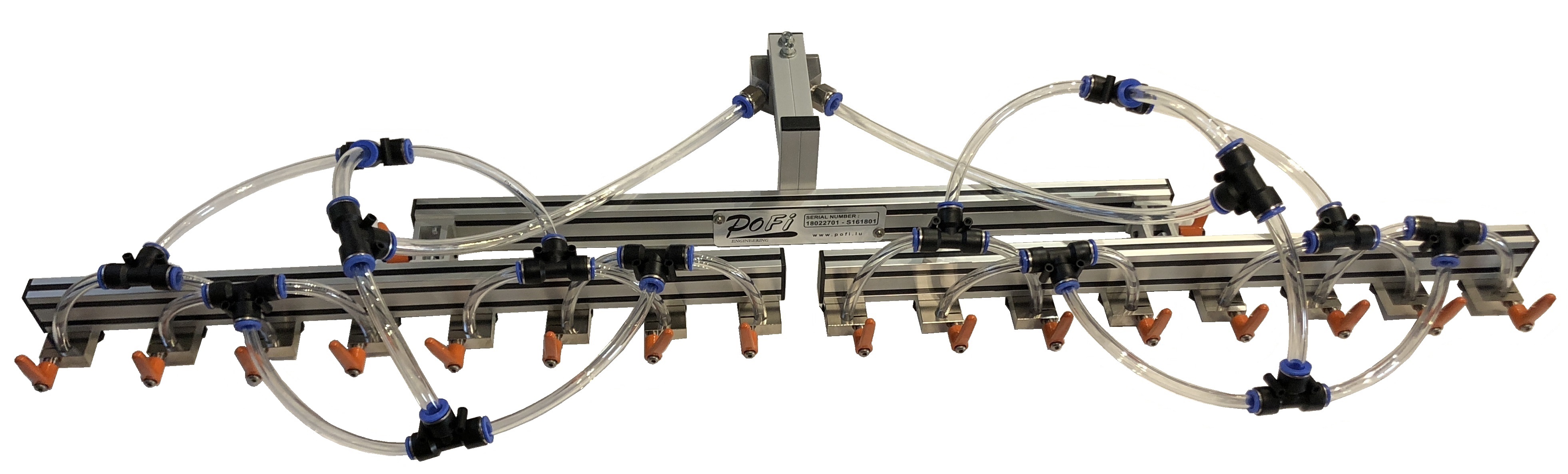

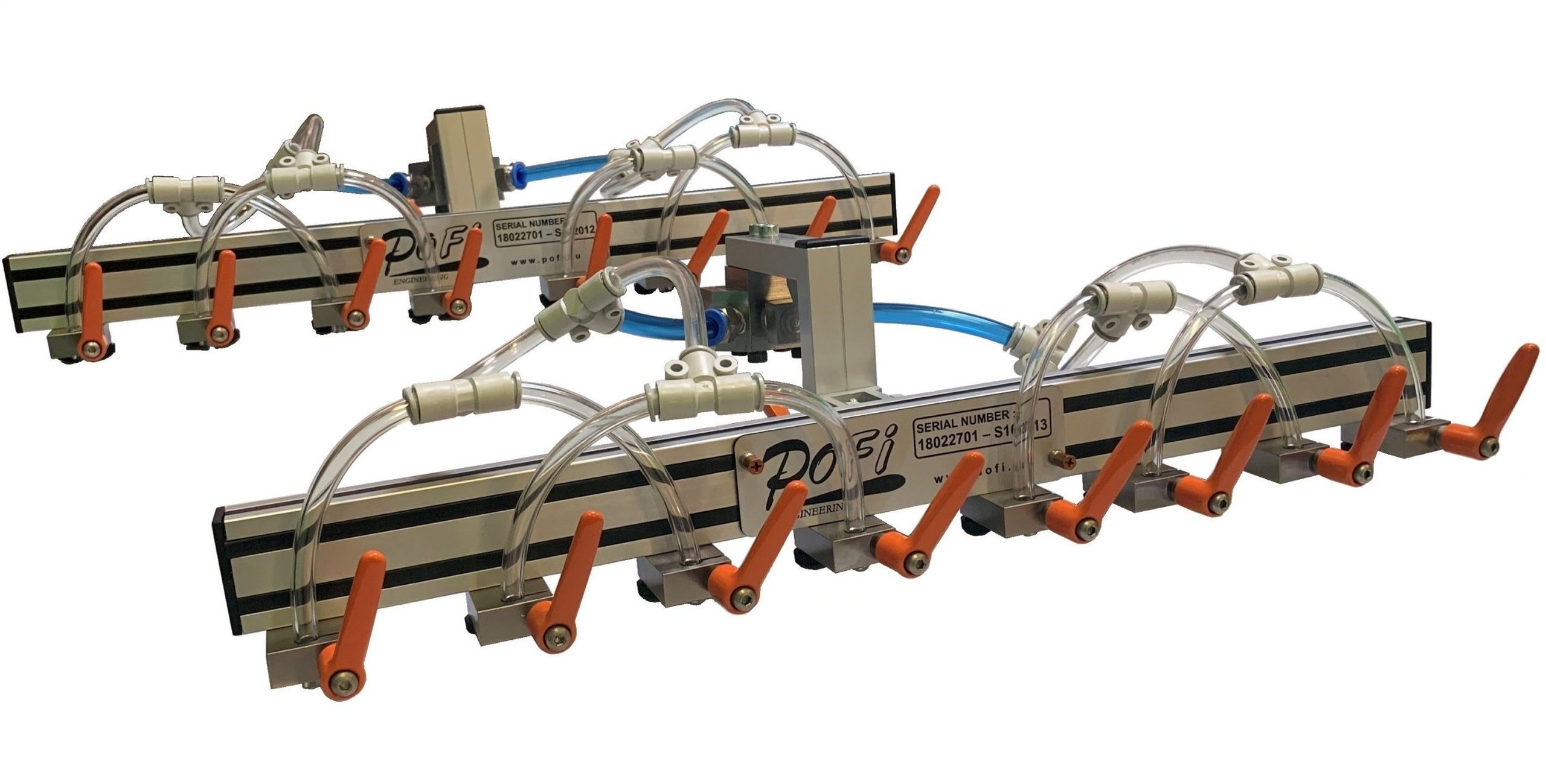

The novelty is the fix foam dispenser, it allows of landing all these problems. The foam is put down on the lower facing in a uniform way and allows of this fact its free expansion. We obtain a homogeneous, well distributed foam and a clear and constant wave. This wave is of this fact easier to control, the global quality of the panel is largely improved. This system needs no movements, so it’s maintenance free.

The position of each point of application is adjustable in width and angle in order to standardize the filling of the panel.

This system is compatible with all existing lines.

Do not hesitate to contact us for more information

_________________________________________________________________________________________________________________________________________________________________________________________________________

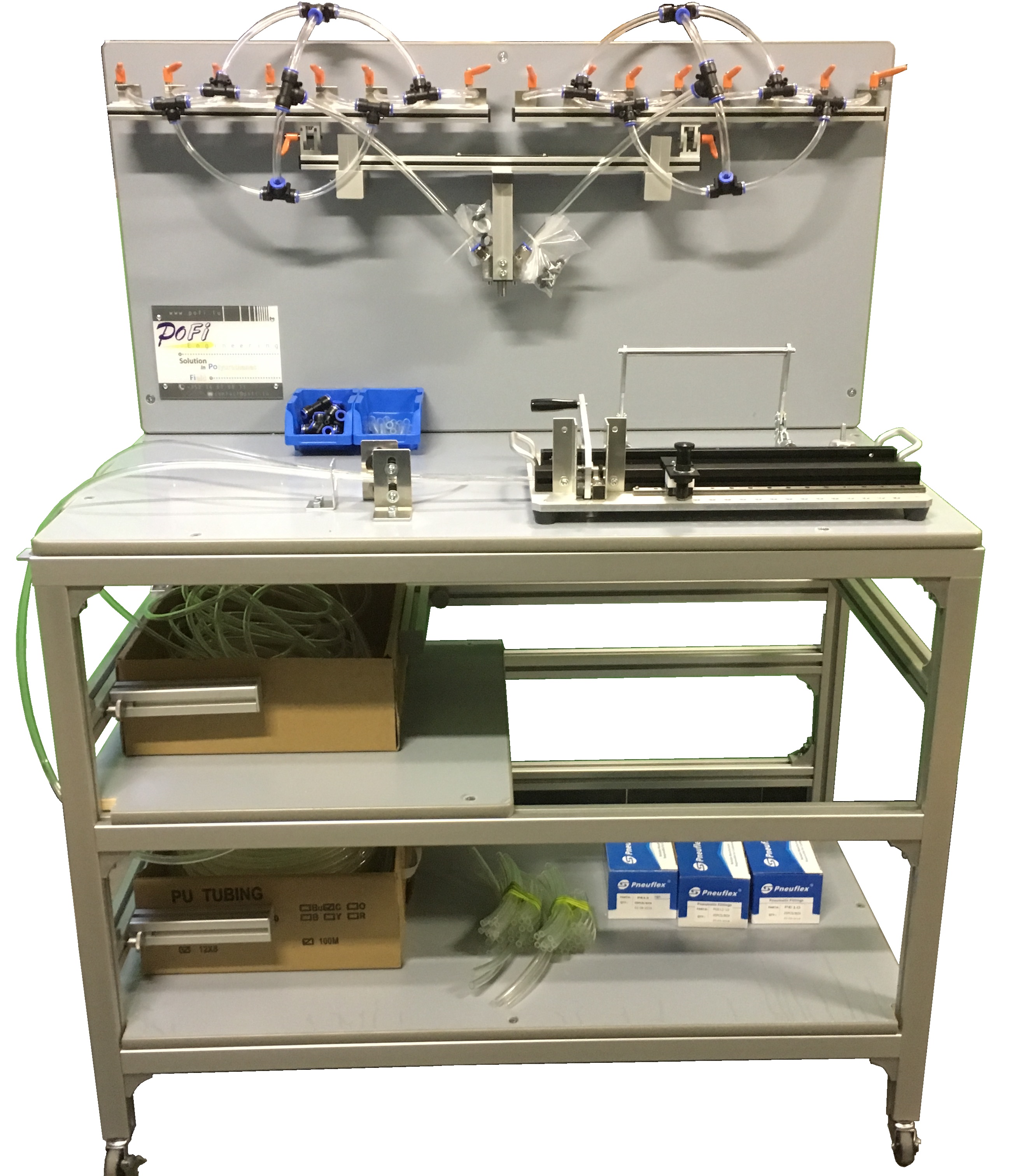

COMPLETE FIXED FOAM REMOVAL KIT FOR SANDWICH PANELS

In order to facilitate the use of our fixed-line foam laying systems, we have developed a work-bench incorporating a fixed head support, a fast and precise cutting system of tubes and storage for fittings and pipes, all at a very affordable price.

- Easy maintenance

- Easy to install

- Time saving

It already exist for small production lines:

____________________________________________________________________________________________________________________________________________________________________________________________________________________________

Importance of polyurethane foam deposit for continuous production

Since the changes of blowing agents due to the new regulations, polyurethane foam become more and more sensitive and complex to pro-duce. The control of its production process becomes a major asset to produce good panels. Among all the production parameters to man-age, I’d like to talk about deposit for which there are two parameters to be well mastered, the polyurethane foam output speed of the dis-penser and the method of removal.

Output speed:

Theory would want that we put down the mixture Polyol and Isocyanate on the lower facing in order not to disturb the chemical reaction in progress. In practice this is not possible, there is a flow from the mixing head outlet and therefore a fluid velocity. The more the speed is high, the less the foam has time to react and therefore clog the dispenser. To increase this speed it is necessary to decrease the size of the outlet ports.

Having a too high fluid exit velocity will generate two problems, the impact velocity on the lower facing will generate air bubbles and the pressure in the mixing head will increase and interfere with the chemical reaction ( mixture). It is not a viable solution.

A theory is that the fluid velocity at the moment of impact must be equivalent to the feed speed of the lower facing. Calculations and tests have demonstrated that this speed is too low to produce, the resident time in the distribution system is too long and the foam has already reacted before touching the lower facing.

A rake (poker) application system generates a speed between 200 and 400 m / min. With other systems the tests have shown that a speed located below 100 m / min provides excellent results but is not achievable with a rake (poker).

The deposit procedure:

Deposit is usually done with a distribution rake (poker) on a swing arm. This method generates many problems, the filling is not uniform and the fluid velocity must be high. The orientation of the cells is not uniform and reduce the mechanical characteristics of the panel.

The fixed deposit is currently the best orientation. The impact velocity is lower and the given angle to the distribution system allows for reduced bubble formation. The uniform arrangement of dispensing dots enables an optimal orientation of cells and thereby to obtain better mechanical characteristics of the panel.