POFI-Engineering has been the exclusive representative of DUT products for Europe for more than 10 years.

Produced in Korea by DUT Korea company, the high pressure mixing heads are known worldwide for their reliability and very favorable price.

Do not hesitate to contact us for more information

Generality:

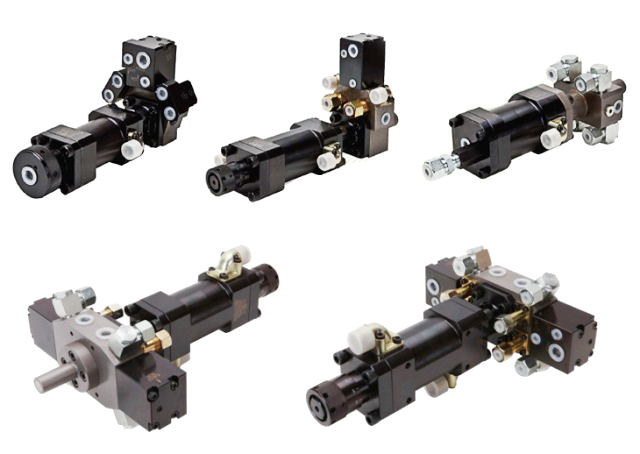

2K ,3K, 4K, 4KS

2K – 2 Components (POL / ISO) with general two nozzle assemblies

3K – 3 Components (POL / ISO / Pigment) with general two nozzle Assemblies and one pigment injector

4K – 4 Components (POL / ISO) with dual head and general fourNozzle assemblies

4KSH – 4 Components (POL / ISO) with general four nozzle assemblies

Features

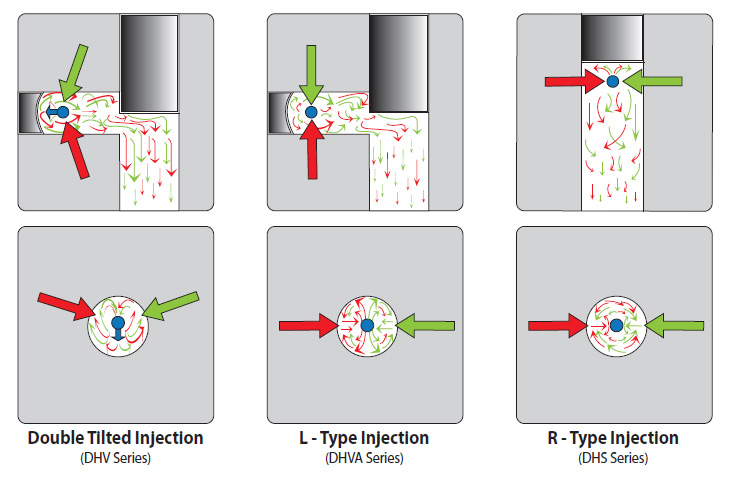

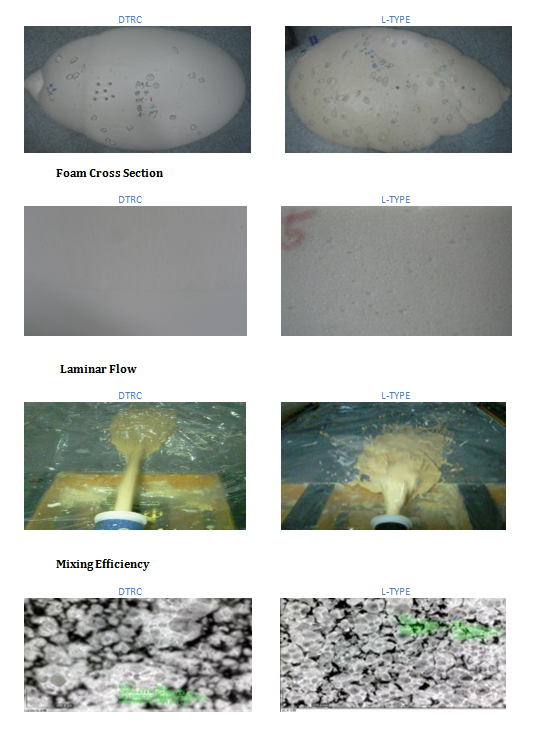

High mixing efficiency by double tilted injection nozzle.

Stable laminar flow-smoothing of the mixture stream & wide laminar range.

Suitable for rigid and flexible foam with low and high viscosity.

Innovative nozzle control for minimum switching times at multi-component.

Economical and reliable.

Long operation life & Low maintenance cost.

Anti-stick locking design and Anti-scrap floating design.

The majority of spare parts are in stock at our premises in Luxembourg to ensure very fast delivery.

Principle of DUT’s Mixing Head