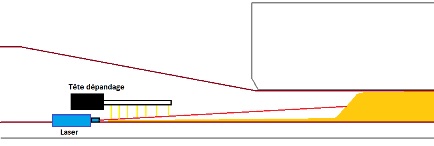

Laser Concept:

The operation of a sandwich panel production line is generally managed by operators, and it is often observed that there are production differences depending on the operator in charge (density, quality, productivity, etc.).

Since the operator has many different tasks to perform, it sometimes happens that the wave moves without them noticing, resulting in poor quality panels.

The laser’s function is to measure the distance between the foam deposition and the wave. Once this distance is set by the operator, the laser takes over and manages the speed of the line to maintain a constant wave position.

If a significant speed correction needs to be made, the laser alerts the operator.

The programmed distance is displayed on a screen and can be stored. It allows verifying the differences in wave positioning based on operators and addressing any potential issues.

During production, the operator is relieved of one task and can focus on other priorities.

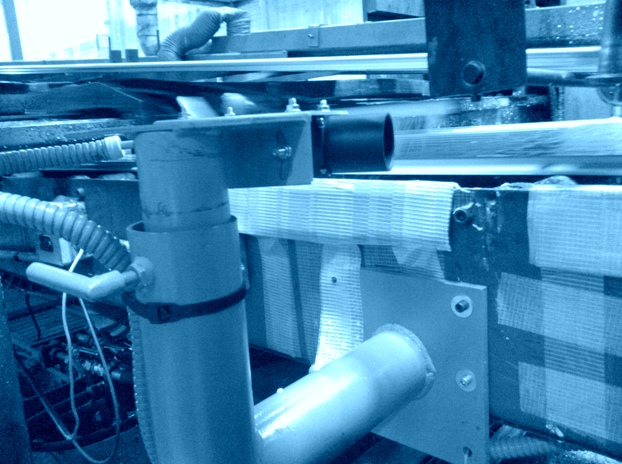

This system is compatible with all existing lines.

.

Feel free to contact us for more information.