Description:

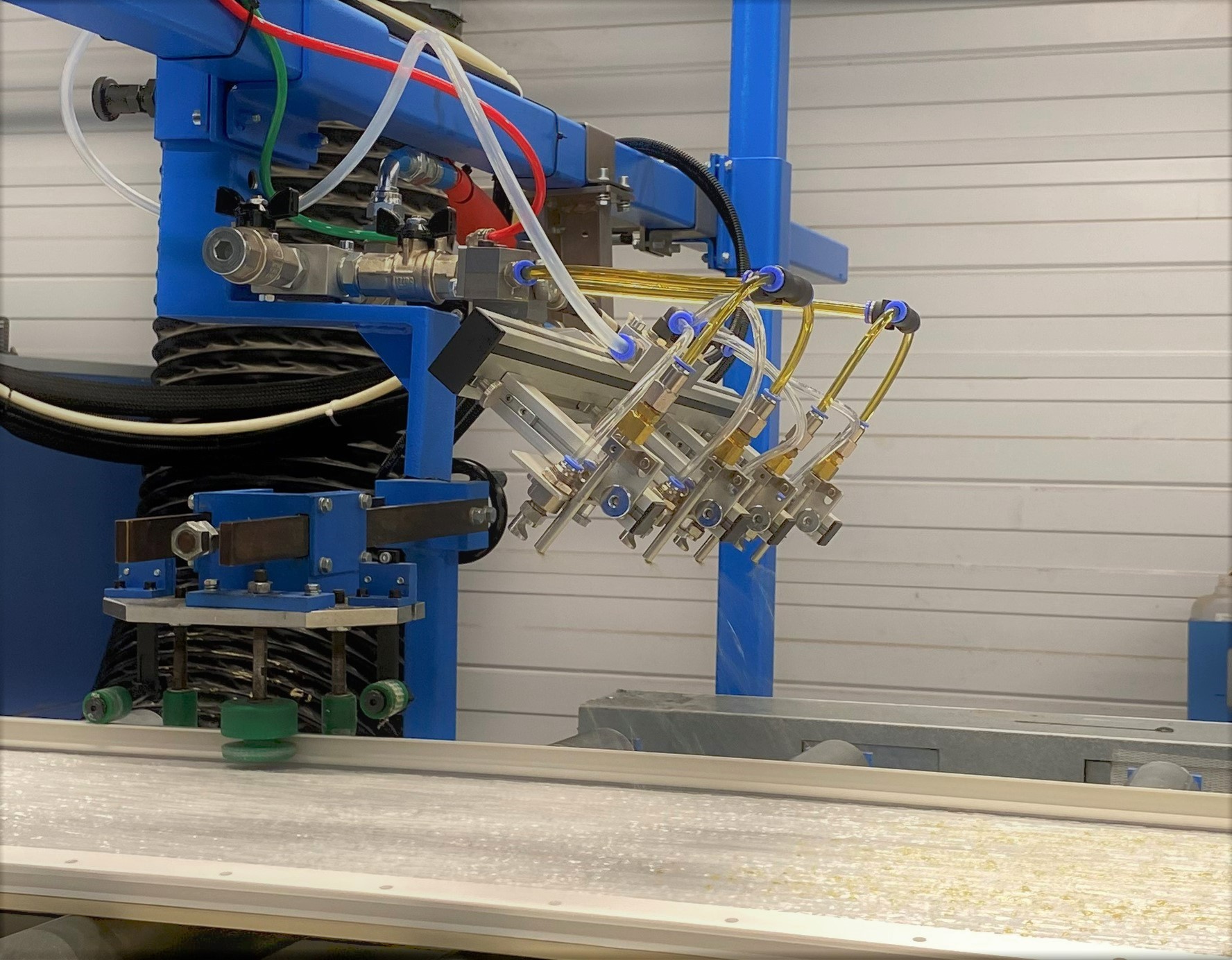

The concept of this system is to allow for the even distribution of fine droplets of adhesive on the lower surface of the panel.

Eight adjustable nozzles create an air cushion parallel to the surface, and on each nozzle, an injector produces fine droplets that randomly land on the panel. There is no spraying of droplets, thus no mist is created.

The dosing device is equipped with a flow meter for each component, and the pump is controlled by a closed-loop controller to regulate the deposited volume.

Cleaning is very easy as there are no mechanical contacts with the adhesive. You can rinse the plastic distribution tubes or replace them.

You can have a pressurized reservoir (for high viscosities) or a transfer pump to work directly from the drum.