Sandwich panel

The main advantages of polyurethane foams are widely their quality of sound and heat insulation, their adhesion on any medium, their flotation power, their capacity to fill the space whatever they are and eto allow custom packaging, light and solids.

Flexible foams are open-celled, they are used as comfort foams, mainly in furniture (chairs, sofas, mattresses)

Rigid foams are closed cell, they are used in isolation or decoration, such as insulation panels (sandwich panels), refrigerators, water heaters, coolers …

The production of construction panels made of rigid polyurethane foam dressed in different siding is rational and profitable. If we use rigid facings on both sides, we obtained in a single operation sandwich panels, which are lightweight, high rigidity and good insulating. Implementation of diffusion-tight facings preserves the good initial thermal conductivity of the rigid polyurethane foam and therefore allows to realize sandwich panels with an optimal insulating power.

The rigid polyurethane foam can be combined with many different types of siding. The range goes from the insulating paper plate laminated to high-end panels with very high insulation designed for cold stores with a foam core up to 250 mm thickness and siding profiles resistant sheet steel warpage.

Polyurethane injection machines are used to mix two components (Polyol and Isocyanate) in a form such as “mold open” or in a form such as “closed mold”.

There are two major families of machines:

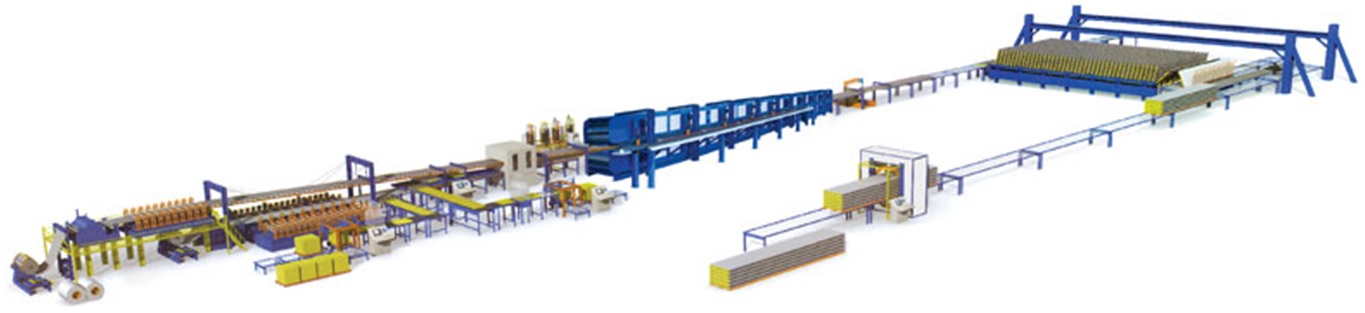

• A continuous casting machine (block foam, sandwich panel, …)

We use for the mass production of panels PUR foam facings dual conveyor installations. These fulfill the function of a support device moving synchronously. They consist of two conveyors with endless chains superimposed and capable of supporting a certain pressure. The space between the two conveyors is adjustable depending on the desired thickness of the panels. Conveyors are heated, the shaper has a length of at least 10 m. This provides mobile area equivalent to a closed press. The press time is dependent on the speed of the conveyor and of its length.

• Casting machines batch (mostly closed mold parts)

The continuous production of sandwich panels on double conveyor installations is especially indicated for large series. Preference is in contrast to the discontinuous manufacture small orders, the specific dimensions for thick elements and when it is necessary to foam the frame of the inserts (windows, solar panels, …) and the fastening elements.